|

YOUR TIRE MAINTENANCE CHECKLIST

(move up

▲)

PRESSURE

(move up

▲)

Under inflation can lead to tire failure. It

results in unnecessary tire stress,

irregular wear, loss of control and

accidents. A tire can lose up to half of its

air pressure and not appear to be flat!

ALIGNMENT

(move up

▲)

A bad jolt hitting a curb or pothole can

throw your front end out of alignment and

damage your tries. Have a tire dealer check

the alignment and damage your tires. Have a

tire dealer check the alignment periodically

to ensure that your car is properly aligned.

ROTATION

(move up

▲)

Regularly rotating your vehicle’s tries will

help you achieve more uniform wear. Unless

your vehicle owner’s manual has a specific

recommendation, the guidelines for tire

rotation are approximately every 6000 – 8000

miles.

TREAD

(move up

▲)

Advanced and usual wear can reduce the

ability of tread to grip the road in adverse

conditions. Visually check your tires for

uneven wear, looking for high and low areas

or usually smooth areas. Also check for

signs of damage.

Log on to www.rma.org for more information

about tire safety.

HOW TO TAKE CARE OF YOUR TIRES

(move up

▲)

Proper tire care and safety is simple and

easy. The rubber manufactures Association (RMA)

recommends getting in the habit of taking

five minutes every month to check you tires,

consult a tire dealer as soon possible.

PRESSURE

It ‘s important to have the proper air

pressure in your tires, as under inflation

can lead to tire failure. The “right amount”

of air for your tires is specified by the

vehicle manufacturer and is shown on the

vehicle door edge, door post, glove box door

or fuel door. It is also listed in the

owner’s manual.

1.

When you check the air pressure, make

sure the tires are cool – meaning they are

not hot from driving even a mile. (NOTE: if

you have to drive a distance to get air,

check and record the tire pressure first and

add the appropriate air pressure when you

get to the pump. It is normal for tries to

heat up and the air pressure inside to go up

drive. Never “bleed” or reduce air pressure

when tires are hot.)

2.

Remove the cap from the valve on one

tire

3.

Firmly Press a tire Gauge onto the

valve.

4.

Add air to achieve recommended air

pressure.

5.

If you overfill the tire, release air

by pushing on the metal a fingernail or the

tip of a pen. Then recheck the pressure with

your tire gauge.

6.

Replace the valve cap.

7.

Repeat with each tire, including the

spare. (NOTE: Some spare tire requires

higher inflation pressure.)

8.

Visually inspect the tires to make

sure there are no nails or other objects

embedded that could poke a hole in the tire

and cause an air leak.

9.

Check the sidewalls to make sure

there are no gouges, cuts, bulges or other

irregularities.

NOTE: Air pressure in a tire goes up (in

warm weather) or down (in cold weather) 1 –

2 pounds for every 10 degrees of temperature

change.

ALIGNMENT

(move up

▲)

Misalignment of wheels in the front or rear

can cause uneven and rapid tread wear and

should be corrected by a tire dealer.

Front-wheel-drive vehicles and those with

independent rear suspension, require

alignment of all four wheels. Have your

alignment checked periodically as specified

by the vehicle owner’s manuals or whenever

you have an indication of trouble such as

“pulling” or vibration.

Also have your tire balance checked

periodically. An unbalanced tire and wheel

assembly may result in irregular wear.

Why Check

Your Alignment?

(move up

▲)

1.

If your cars suspension system is out

of alignment, your tire will wear unevenly

and you may experience handling problems.

Potholes and rough roads can contribute to

the problems with alignment.

2.

Front-wheel drive vehicles and those

with independent rear suspension. Require

alignment of all four wheels.

3.

Have a tire dealer check your

alignment periodically as specified by your

vehicle’s owner manual or if handling

problems develop, such as “pulling” or

vibration.

4.

Also have your tire balance checked

periodically. An unbalanced tire and wheel

assembly may result in irregular wear

ROTATION

(move up

▲)

Sometimes irregular tire wear can be

corrected by rotating your tires. Consult

your vehicle owner’s manual, the tire

manufacturer or your tire dealer for the

appropriate rotation pattern for your

vehicle. NOTE: If your tires show uneven

wear, ask your tire dealer to heck for and

correct any misalignment, imbalance or other

mechanical problem involved before rotation.

Before rotating your tires, always refer to

your vehicle owner’s manual for rotation

recommendations. If no rotation period is

specified, tires should be rotated

approximately every 6000-8000miles.

Why Rotate

your tires?

(move up

▲)

1.

Each tire on your car support a

different amount of weight, this unequal

weight distribution causes your tires to

wear at different rates. By rotating your

tires, you can extend their useful life.

2.

If your tires show uneven wear, ask

your tire dealer to check for and correct

any misalignment, imbalance or other

mechanical problem involved before rotation.

3.

Refer to your vehicle’s owner manual

for rotation recommendations. If no rotation

period is specified, tires should be rotated

approximately every 6000 miles.

4.

Sometimes front and rear tires use

different pressure. After rotation, adjust

individual tire air pressure to the figures

recommended for each wheel position by the

vehicle manufacturer.

TREAD

(move up

▲)

Tires must be replaced when the tread is

worn down to 1/16 of an inch in order to

prevent skidding and hydroplaning. An easy

test: place a penny into tread groove. If

part of the Lincoln’s head is covered by the

tread, you’re driving with the proper amount

of tread. If you can see all of his head,

you should buy a new tire.

Built-in tread wear indicators. Or “wear

bars,” which look like narrow strips of

smooth rubber across the tread will appear

on the tire when the tread is worn down to

one-sixteenth of an inch. When you see the

“wear bars,” the tire is worn out and should

be replaced.

Visually check your tires for signs of

uneven wear you may have irregular tread

wear if there are high and low areas or

unusually smooth areas. Consult your tire

dealer as soon as possible.

OTHER

IMPORTANT INFORMATION

(move up

▲)

Practice good driving habits, which will

help keep your tries in good condition.

-

Obey posted speed limits.

-

Avoid fast starts, stops and turns.

-

Avoid potholes and other objects on the

road.

-

Do not run over curbs or hit your tires

against the curb when parking.

-

Do not overload your vehicle. Check your

vehicle’s tire information in the

owner’s manual for the maximum

recommended load for your vehicle.

If properly cared for, tires can last a long

time usually from 40000 to 80000 miles,

depending on the application.

Tires and

Auto Safety

(move up

▲)

1.

Number of tires on the road in

America in 1999 on non-commercial vehicles

(cars and light trucks, including SUV) : 882

million

2.

Number of tires shipped in 1999 : 316

million

3.

Miles driven by non-commercial

vehicles in 1998 :2.4 trillion

4.

Occupant fatalities in 1999 in cars

and light trucks :35,806

5.

Number of fatalities in 1999 that

involved “tire related factors” :647 or 1.8

percent

6.

Recommended frequency for visual

inspection and air pressure check of all

four tires and the spare : one a month and

before every long trip.

*(Sources: National Highway Traffic Safety

Administration, Rubber Manufacturers

Association)

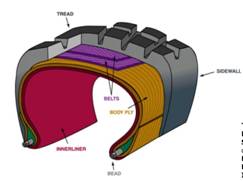

WHAT IS INSIDE A TIRE?

(move up

▲)

Tread:

Provides traction and cornering grip

Belts:

Stabilize and strengthen the tread

Sidewall: Protects the side of the

tire from road and curb damage

Body Ply: Gives the tire strength and

flexibility

Bead: Assure an air-tight fit with

the wheel

Inner liner: Keeps air inside the

tire

Modern tire technology blends a unique mix

of chemistry, physics and engineering to

give consumers a high degree of comfort,

performance, efficiency, reliability and

safety. Many tires are custom designed to

meet the stresses and performance needs

specified by the maker of a particular model

vehicle. Every tire is carefully inspected,

and random samples are pulled for additional

safety tests. As part of these tests, tires

are x-rayed, cut apart and examined, run on

test wheels, or road-tested to evaluate

handling, mileage and traction performance.

If properly cared for, tires can last a long

time- usually from 40000 to 80000 miles,

depending on the application.

HOW A TIRE IS

MADE

(move up

▲)

As many as two hundred different raw

materials combine into a unique mix of

chemistry, physics and engineering to give

consumers the highest degree of comfort,

performance, efficiency, reliability and

safety modern technology and creativity an

provide. Here are the basic steps:

PLANNING AND

DESIGNS

(move up

▲)

Many tires are custom-designed to meet the

stresses and performance needs specified by

the maker of a particular model vehicle. The

process begins with a computer, which

converts the mathematics of a car’s special

needs into specifications. A prototype tire

is then made to test the tire design’s

ability to provide the desired

characteristic. Custom-designing a tire for

a particular vehicle typically takes many

months of testing, inspection, and quality

checks by the tire maker and the vehicle

maker. Only then does the vehicle maker

commit with an order.

MANUFACTURING

(move up

▲)

The production process begins with the

selection of several types of rubber along

with special oils, carbon black, pigments,

antioxidants, silica and other additives

that will combine the various raw materials

for each compound into a homogenized batch

of black material with the consistency of

gum. The mixing process is

computer-controlled to assure uniformity.

The compounded materials are then sent to

machines for further processing into the

sidewalls, tread or other parts of the tire.

Then the task of assembling the tire begins.

The first component to go on the tire

building machine is the inner line, a

special rubber that is resistant to air and

moisture penetration and takes the place of

an inner tube. Next come the body piles and

belts, which are often made from polyester

and steel. Plies and belts give the tire

strength while also providing flexibility.

The belts are cut to the precise angle and

size the tire engineer specifies to provide

the desired ride and handling

characteristics. Bronze-coated strands of

steel wire, fashioned into two hoops, are

implanted into the sidewalls of the tires to

form the bead, which assures an airtight fit

with the rim of the wheel. The tread and the

sidewalls are put into position over the

belt and body piles, and then all the parts

are pressed firmly together. The end result

is called a “green” or uncured tire.

The last step is to use the tire. The green

tire is placed inside a mold and inflated to

press it against the mold, forming the tread

and the tire identification information on

the sidewall. Then it is heated at more than

300 degrees Fahrenheit for twelve to fifteen

minutes, vulcanizing it to bond the

components and to cure the rubber. (FACT:

This twelve to fifteen minute curing process

is for passenger and light truck tires

size!)

Every tire is then inspected, and sample

tire are randomly taken from the line and

tested. Some are x-rayed, some are cut apart

to look for flaws, others are run on test

wheels, or road-tested to evaluate handling,

mileage and traction performance.

SAFETY

PRECAUTIONS

(move up

▲)

1.

Always fit correct size &type of tyre

recommended by vehicle Manufacturer.

2.

Check all tyre pressure including

spare tyre at least one in every 15 days.

3.

Maintain tyre pressure as per

vehicles specification to ensure optimum

life out of tyre & safety drive.

4.

Check & adjust all tyre pressure when

tyres are cold i.e. early morning & not when

tyres are hot .

5.

Never reduce air pressures from tyres

during summer season or let out any air from

hot tyres

6.

Always fix new tyres on front axle &

never mix tyres of different make &

structure on same axle as it affects braking

ability.

7.

Always rotate tyres from front axle &

vice versa at 15000 KM to minimize irregular

wear & increase tyre life.

8.

Never use worn out tyres or old

second hand tyres as it is very dangerous to

drive on them, change them promptly.

9.

Always put a valve cap on tyre of

tubeless tyres.

10.

Always put a new tube in new tube

type tyres, never fit it without a tube i.e.

as a tubeless.

|